Precision Aero Services

FAA Repair Station P0VR332Y

CAGE 665Z9

1323 Hwy. U

Bolivar, MO 65613

Tel: 417.326.2376

Fax: 417.326.2377

Toll Free: 855.727.2376

Our Repair Fleet Experience:

Boeing:

B727, B737, B747, B757, B767, KC135, C17, CH46, CH47

Bombardier:

BD700, CL600, CL601

Dornier:

DORNIER 328

Gulfstream:

G200, GII, GIII, GIV, GV

Hawker:

HS125 600/700, HS125 800/850, HS125 800SP, HAWKER1000

Dassault Falcon:

Falcon 10, Falcon 20, Falcon 200, Falcon 900, Falcon 2000

FAA Repair Station P0VR332Y

CAGE 665Z9

1323 Hwy. U

Bolivar, MO 65613

Tel: 417.326.2376

Fax: 417.326.2377

Toll Free: 855.727.2376

Our Repair Fleet Experience:

Boeing:

B727, B737, B747, B757, B767, KC135, C17, CH46, CH47

Bombardier:

BD700, CL600, CL601

Dornier:

DORNIER 328

Gulfstream:

G200, GII, GIII, GIV, GV

Hawker:

HS125 600/700, HS125 800/850, HS125 800SP, HAWKER1000

Dassault Falcon:

Falcon 10, Falcon 20, Falcon 200, Falcon 900, Falcon 2000

Management Team

Call us at 417-326-2376 for more information.

Precision Aero Services - Nationwide

Precision Aero Services provides composite repair and aircraft parts to Miami, FL, Los Angeles, CA, St Louis, MO, Dallas, TX, Houston, TX and Las Vegas, NV as well as the surrounding areas.

Precision Aero Services provides composite repair and aircraft parts to Miami, FL, Los Angeles, CA, St Louis, MO, Dallas, TX, Houston, TX and Las Vegas, NV as well as the surrounding areas.

Kenny Zeagler began his aviation career in 1995 coordinating all repairs and overhauling for Boeing, Douglas, Airbuse, Gulfstream, Hawker, and Falcon flight controls at Aerocell Structures, Inc. In addition, Kenny also served as Production Control Manager at Aerocell until 2000 where he reviewed planning and technical data (OHM, SRM, IPC, and drawings) and coordinated and reviewed all parts fabrication. Kenny left Aerocell in 2001 with the title of Director of Inside Sales, customer support, and all aspects of estimating and quoting. Kenny started his own FAA Repair Station; as the Business

Kenny Zeagler, President and Co-Owner

Manager he was responsible for all aspects of company operations including training, proper testing of tools and equipment, and the completion of all repairs, maintenance, and alterations of airframe components/appliances in accordance with FAR’s manufacture’s specifications. Kenny was also responsible for the planning, organizing, and staffing for all repair station projects as well as securing the supervision, manpower, and adequate facilities for all repair projects. In 2010, Kenny became President of Precision Aero Services, Inc. of Nevada, Missouri and in October of 2011 Kenny, relocated Precision Aero Services, Inc. to Bolivar, Missouri opening a larger, more advanced facility.

Rocky Herring, Engineering and Quality Manager

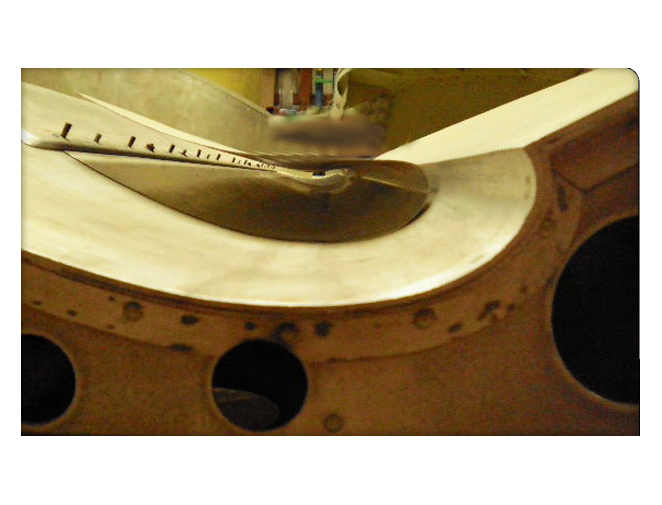

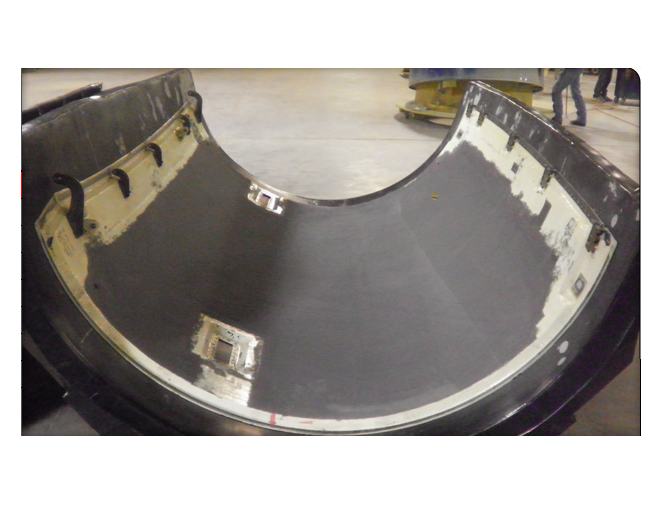

Rocky Herring has an extensive background in electronics and mechanics originally specializing in agricultural equipment. Rocky spent 8 years at O’Sullivan as Maintenance and Safety Manager and has been with Precision Aero Services, Inc. since 2004. In his early work at Precision Aero Services Rocky was in charge of the construction and servicing of the autoclave and installation and mechanics of the PAA etchline. Rocky also has over 24 years experience in Auto Cad 2D and 3D. In 2005 he began engineering the repair of inlets and fan cowls of the KC 135.

He creates work instructions and procedures, and his responsibilities have included the certification of the autoclave and etchline, he serves as a walk-along for repair station audits, uniformity surveys, and ensures all safety and quality requirements are met. Rocky over sees the engineering aspects on all repairs and ensures staff training and safety requirements are continuously up-to-date.

Tony Murphy, Maintenance Supervisor

Tony Murphy has a vast and knowledgeable background in aircraft maintenance. Prior to working with Precision Aero Services, Tony worked for Boeing Wichita Facility as an aircraft inspector on military modification programs such as E4B, VC25, and C40. He held the position of Quality Assurance Rep for the Used Aircraft Sales Team as well as the 767 tanker program.

He is familiar on 737, 757, 747, MD11, DC10, A320, and the A340. Tony has excelled in management capacities in both

He is familiar on 737, 757, 747, MD11, DC10, A320, and the A340. Tony has excelled in management capacities in both

production and quality while at the Wichita Modification Repair Center. His duties included overseeing and ensuring aircraft repairs and upgrades which met FAA/ JAA/ EASA standards prior to delivery of used aircraft to their customers, coordinated efforts with numerous outside vendors and a variety of Boeing agencies for purposes of procurement meeting all delivery schedules. Tony is familiar with the repair station operations of both FAR 145 and FAR 121 facilities. He is also familiar with aircraft operations, engine systems, avionics systems in relation to flight indications and navigation, weight and balance, and received his A&P Certificate 11/03/2008.

Tony and his select staff repair and overhaul all of the parts here at our facility. He ensures technicians are trained and equipped for the task ahead. He along with all other staff go through training before working your parts or assemblies. As supervisor, he wants to make sure the job is completed on time and completed right.

Tony and his select staff repair and overhaul all of the parts here at our facility. He ensures technicians are trained and equipped for the task ahead. He along with all other staff go through training before working your parts or assemblies. As supervisor, he wants to make sure the job is completed on time and completed right.

Cynthia Fowler, Office Manager

Cynthia Fowler has over 15 years in the office setting. During high school she took classes on Excel and Power Point and after Graduation, she went to work for a graphics company

specializing in silk-screening where she was trained in inventory, purchasing, invoicing, shipping and receiving, and utilized her organizational skills. After leaving that company, she worked free-lance and specialized in setting up books and office management and filling systems for others. Cynthia started at Precision Aero Services as an office assistant and quickly worked her way up to the position of

specializing in silk-screening where she was trained in inventory, purchasing, invoicing, shipping and receiving, and utilized her organizational skills. After leaving that company, she worked free-lance and specialized in setting up books and office management and filling systems for others. Cynthia started at Precision Aero Services as an office assistant and quickly worked her way up to the position of

office manager. Her jobs include office and shop organization, customer service, human resources, purchasing/ procurement, Accounts Receivable/ Accounts Payable, inventory, and shipping and receiving. Cynthia is inspired to do the best she can as the Office Manager and will be here to help Precision Aero Services grow as a company, but most of all, grow as a team.